Rural Water Supplies with Difficult Sources

INTRODUCTION

Out Skerries is a group of three small islands with a population of approximately 100 inhabitants in the extreme most northerly tip of Scotland, 30 miles due northeast of Shetland. This location presents issues of remoteness and requires consideration of the sensitive environmental context.

The Islands, all connected by bridges, had an existing high-level water treatment works employing media filtration, which regularly failed to produce water to potable standards due to high concentrations of colour leading to the creation of carcinogenic disinfection byproducts. The raw water source was a rainwater runoff collection trough circling the main hill on the largest island, which supplied the works via an impounding storage reservoir and auxiliary steel tank. The treated water was then distributed via a network serving the three islands. In addition to poor water quality, the islands suffered from shortages of water volumes during extended dry periods.

CHALLENGE

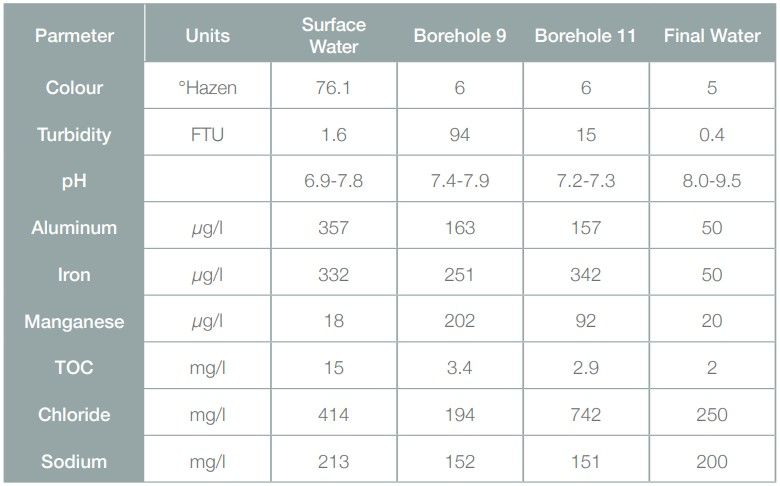

To overcome the shortcomings of the existing system, North of Scotland Water required improvements to be made in both drinking water quality and the available raw water quantity. The rainwater collection trough was recognized as being inadequate to provide the required security of supply, hence it was decided to drill ground water abstraction boreholes to augment this source. In total fourteen boreholes were drilled and subjected to hydrogeological testing, of which the two most suitable were selected (numbers 9 and 11). Most of the boreholes were found to have very poor water quality and/or insufficient yields and hence could not be used. The proximity of the sea caused all of the boreholes to exhibit relatively high salinity, as did the rainfall collection trough due to salt spray during windy weather. The runoff collection system caused organic pollutants in the soil to contaminate the raw water, which was further exacerbated by infiltration into the impounding reservoir. The raw water quality of the three sources, together with the product water quality specification, has been tabulated opposite.

It was decided that the borehole sources would be employed for 10 hours per day (subject to conductivity limits), with the surface water runoff collection system being used to top-up supplies and hence meet demand. The challenge was to provide an environmentally sensitive process solution capable of treating any of the three sources in whatever mix of raw water volumes was available, to continuously comply with the product water quality specification.

CONTRACT AWARD

North of Scotland Water employed leading industry consultant Hyder Consulting to develop a tender and select appropriate organisations with suitable technologies for this challenging situation. PCI Membranes was awarded the contract as a result of the customer’s and consultant’s confidence in the technical solution and the lowest whole life costs offered. PCI Membranes’ extensive track record in this field of water treatment and commitment to supporting the customer were also instrumental in the success.

Not only was the Fyne process’ innovative foam ball cleaning system ideally suited to this pristine environmental context (enabling all wastes to be disposed of to the local environment), but also the wealth of membrane technology experience that exists in PCI Membranes enabled the technology to be optimally applied in these unique circumstances. In addition to the design, build, installation and commissioning of the Fyne water treatment process, the contract included equipping the boreholes with abstraction plant and head works.

DESIGN

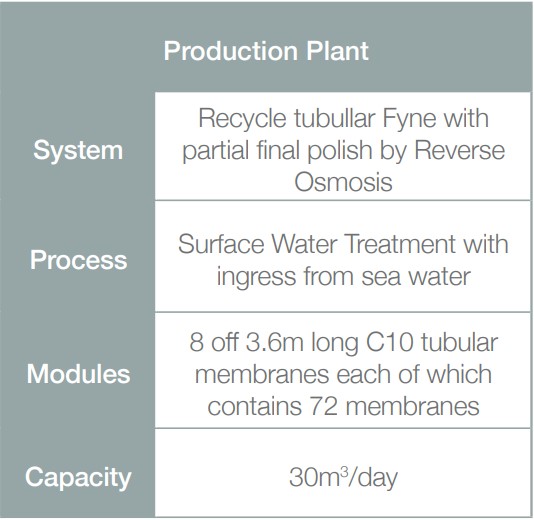

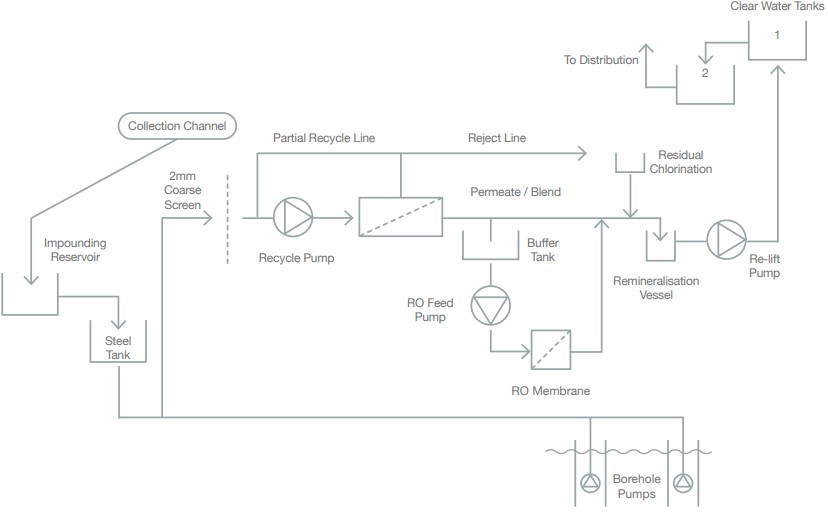

The treatment plant design comprised a primary nanofiltration tubular membrane process to remove colour and metals, followed by a secondary low pressure Reverse Osmosis (RO) spiral wound membrane polishing stage (treating 40% of the design flow rate) to reduce the concentration of dissolved salts. This combination ensures that the product water, which is a blend of the membrane plants’ permeates, complies with drinking water quality standards. It also minimises the need for cleaning chemicals to regain the filtration performance of the RO stage by reducing the contaminant load sent to it, and therefore its size. Following post treatment disinfection and conditioning, the flow is re-lifted to clear water storage tanks prior to distribution.